ESD-Safe Cleanroom Coveralls are Designed for Use in Controlled Environments When Static Control is Paramount.

Cleanrooms, typically utilized for scientific research or specialized industrial production, require specific PPE that limits contamination and provides multi-faceted protection. Transforming Technologies TX4000 ESD Cleanroom Garment System protects the environment from the number one source of contamination and static found in cleanrooms – people. Electrostatic charge is an invisible contaminant and has the potential to degrade or destroy both product and equipment, as well as attract unwanted particles. Controlling these charges with the TX4000 Garment System throughout the controlled environment is essential to a productive manufacturing process.

Static Control From Hood-To Boot

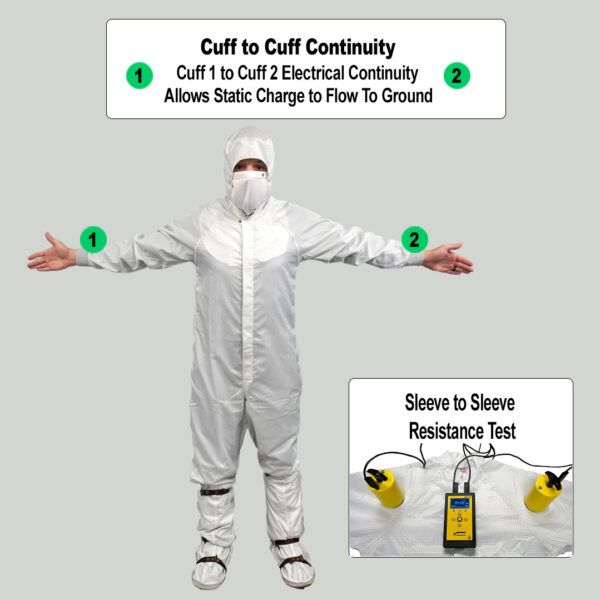

Typcial ESD-Safe Cleanroom Garments use a static dissipative fabric, but little concern is made with the electrical continuity between fabric panels and the components such as the hood, or boots. Due to the lack of continuity, a static charge originating on the hood may not be able to dissipate through the coverall and boot to be eliminated via the grounded floor. This is referred to as a isolated conductor

TX4000 solves this issue. Groundable from hood-to-boot, the TX4000 ESD Cleanroom Garment System is made with a reliable ISO 6 static dissipative fabric with each component—hood, coverall, boots—electrically connected with conductive threads and ground snaps. A superior conductive sole on the boot eliminates static on the personnel through the ESD floor or mat quickly and safely. The garments system’s superior workmanship and reliable panel-to-panel continuity makes it compliant with IEST-RP-CC052 and ANSI ESDS.2020 standards. The TX4000 Garment System maintains consistent continuity readings for up to 100 wash cycles